Mud agitators - PG Submix

PG developed the first Submix agitators in the 80’s, and we are now in the third generation of these.

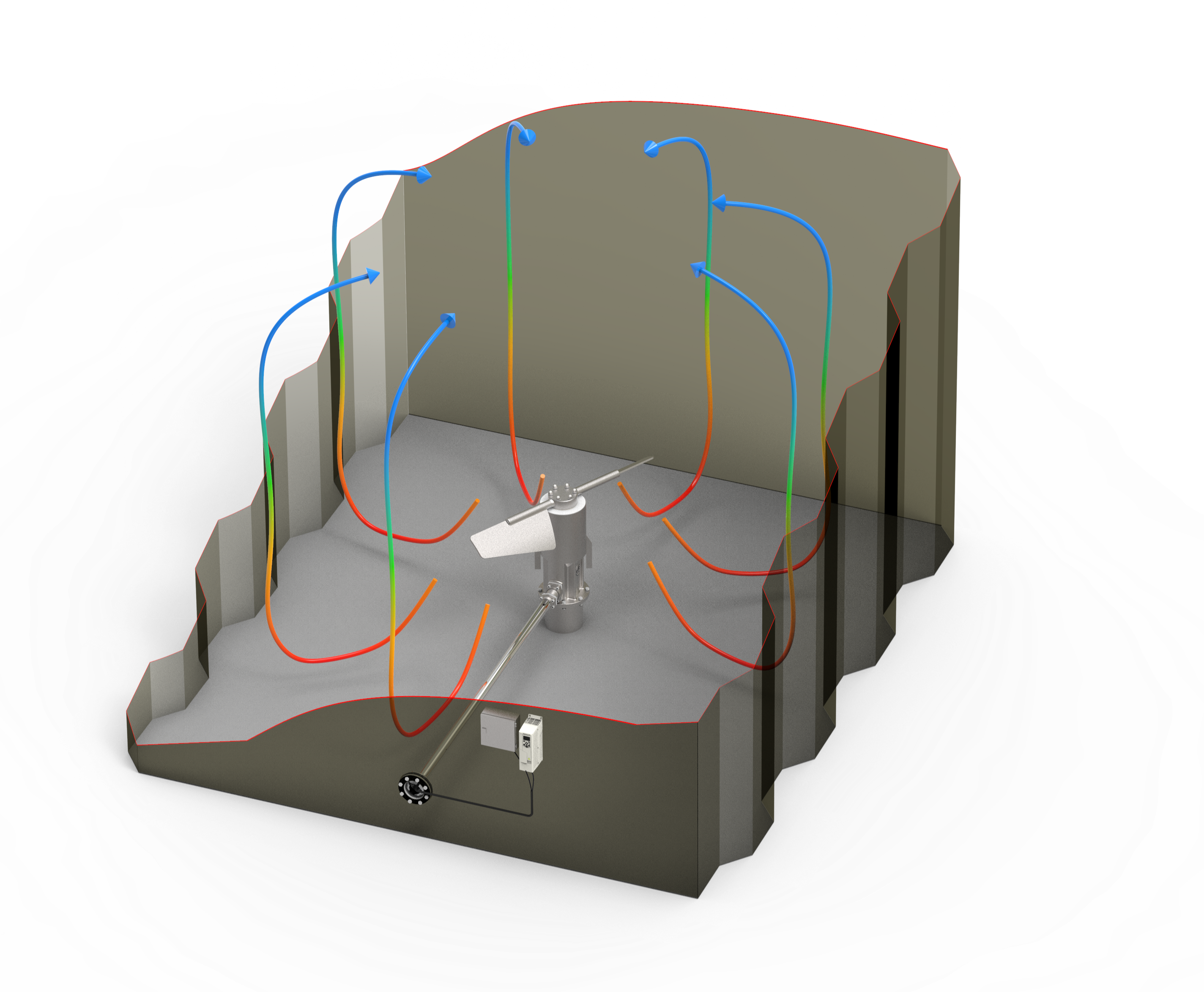

Differently from the a.m. electric propeller type solution (which create an angled horizontal spiral in the tank), the Submix-units create a vertical circulation by gently moving the liquid by low speed, high torque towards the bottom of the tank generating the highest energy / velocity there to lift, mix and agitate the mud at very high quality.

Both the shear-forces and cavitation issues are at completely different levels compared to propeller type units. The latter making these units highly attractive also to keep special chemicals, polymers and other high value cargo in controlled suspension.

Read more: Typical mixing processes we solve

The rugged design of these units, allow for completely different experiences related to the a.m. influxes, as both the speed at which they work, their mere construction and the much higher torque are handling these issues with ease. The PG-Submix units have also proven exceptionally well in the Recovered Oil situations we have seen, being able to keep the emulsion pumpable for efficient discharge.

Commercially the Submix-units are not far from a.m. electric propeller types, but do require a HPU and a small control system in addition.

Due to the very high efficiency of these units, we often see that one PG-Submix is able to do the work (or even better) of two or more electric propeller type units.

Download product sheet:

PG-SUBMIX

The Primary Pump Flow (PPF) for our PG-Submix 60/80 Viscoprop 35° are typically

- The PG-Submix 100-2800 have a PPF = 0.59 x 33 x 60 x 2,8³ = 25.644 m3/h each

- The PG-Submix 80-2200 have a PPF = 0.59 x 33 x 60 x 2,2³ = 12.439 m3/h each

- The PG-Submix 60-1800 have a PPF = 0,59 x 41 x 60 x 1,8³ = 8.465 m3/h each

Which gives an unsurpassed suspension, over long time and with the heaviest mud we have seen in the market place.

More important though, is the principle working method of these heavy-duty-units, in which all energy / thrust created is pointed to the bottom of the tanks, creating max velocities well surpassing settling speeds in the most critical areas of exposure.

Recovered Oil capacities;

Also of highest value in these equations, the future demands for stand-by-capacity for Recovered Oil is very challenging. The PG-Submix agitators may be used to keep the water-emulsion-heavy oil mixed, in suspension – hence pumpable when at discharge, which will reduce discharge time and turn-around of the vessels significantly.

We – and many of the larger Ship Owners in the global market – see the solutions to this; not in building dedicated OSRV’s – but enhancing the total capacities available on the entire OSV-fleet.

Needless to say: these are perfect match for PG-MACS, which allow all cargo tanks to carry Recovered Oil – which could easily allow a PSV 4500 to carry in excess of 2.000m3, if designed properly. A fleet of such vessels would eliminate the need of many OSRV’s, and save a lot of money in chartering.