Tank cleaning solutions

A fully automatic PG mud cleaning system enable the operator to clean the tank immediately after discharge before solidification etc may occur. This mean that the tanks are basically ready to take new cargo when arriving to port. The log function will enable the operator to optimize the cleaning procedure for each type of mud and reuse the cleaning program that have been found to give sufficient cleaning results. Hence repeatability of best practice will be possible compared to manual cleaning that is dependent on who is making it etc.

By having a cleaning procedure that start cleaning with mud followed by use slop that is recirculated will minimize the amount of slop that has to be discharged after cleaning.

Automatic cleaning system with fixed machines enables the operator to make cleaning with closed hatch conditions and will not expose humans to possible hazardous gases etc. Closed hatch cleaning will also reduce the risk for explosion depending on type of cargo in the tanks. Timely manual cleaning may be avoided.

To conclude above: The operator will have less down time due to cleaning operation, create less slop and avoid human exposure of possible toxic gases.

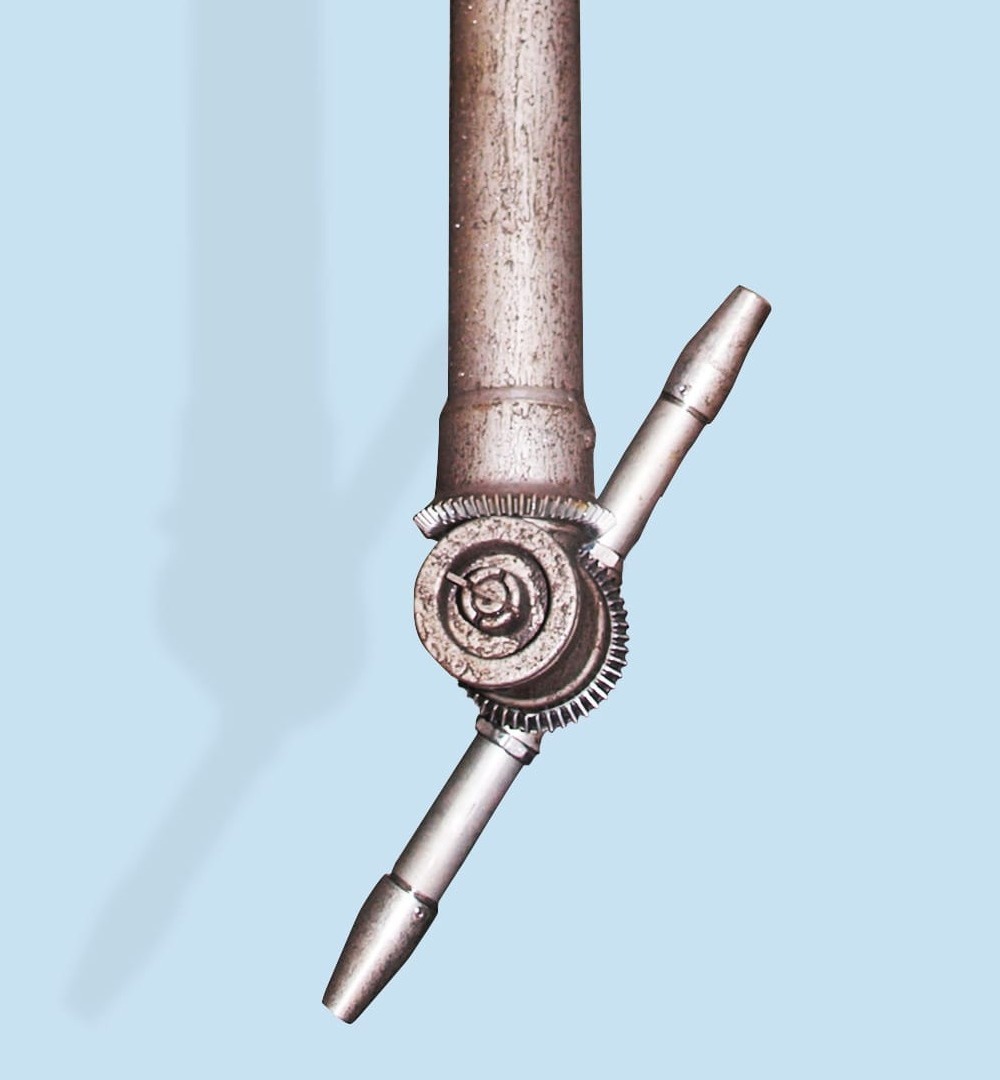

PG present the widest range of solutions to your tank cleaning challenges, all from simple liquid driven nozzle machines, up to remotely operated, fully feed-back, hydraulically driven ATEX approved solutions